With headphones, the wire is considered the most vulnerable point. From frequent bending copper wires are broken and one or two speakers stop sounding. To repair the headset, you must first locate the break. The search is simple: feel with your fingers or a multimeter. And here's how to connect the wires of headphones, if they are broken we, now consider.

Content:

Locating a break

If the speaker makes a crackling noise or is silent, you can say with 99% certainty that there was a wire breakage. You should not mess around with cheap Chinese earphones. It is easier to throw them away. Expensive headsets are worth an attempt to repair. There are two ways to find the breakage.

Recommendations:

How to protect headphones from mechanical damage and strengthen the wire

, How to solder the headphones plug

, How to solder the headphones plug

, How to fix headphones yourself if one stops working

, How to fix headphones yourself if one stops working

Simple Probing Search

The first method of searching is based on probing the cable with your fingers. The headset is plugged into a cell phone and playing a music file. The entire length of the cable, from the plug to the headphone inlet, is crisscrossed with your fingers.

When the non-functioning speaker makes a crackling or intermittent sound, the section of the wire being diagnosed is marked for repair. The search method will yield results if the fractured cores are far from separated from each other inside the insulation.

Multimeter Search

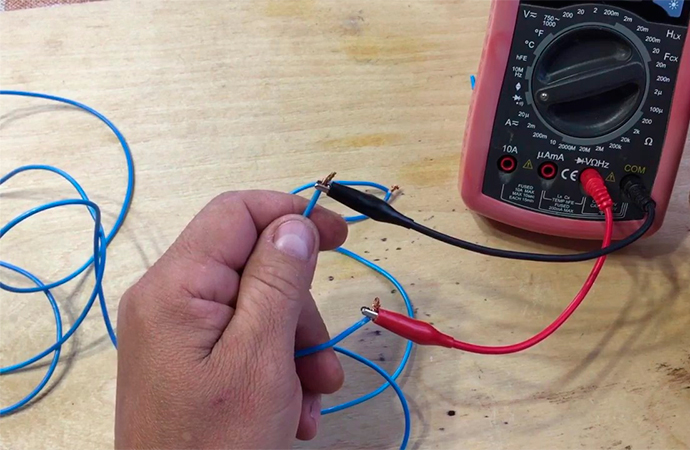

The second method is justified when the search by probing did not give results. If the cable is caught while walking, a jerk occurs. The copper core breaks and the insulation stretches. Probing won't help. The ends of the cores are distant from each other and will not come close when the cable is crisscrossed.

Search for a break with a multimeter:

- To wire a cable with a multimeter, you will have to peel off the insulation in places. The method is aggressive, but there is no other choice. It is advisable to try to disassemble the headphone, so as to first test the entire cable from the contacts of the loudspeaker to the metal part of the plug. If there is a signal on the multimeter, it means that the cause is in the speaker and the wire should not be cut.

- If there is no signal or if it is impossible to disassemble the headphone, cut the insulation. Core fracture most often occurs near the plug, the speaker or on the wire bifurcation. To check the plug, remove 5 mm of cable insulation at a distance of 5 cm from the headphone. You have to be careful with the stripping, otherwise the thin wire will be damaged. One probe of the multimeter is leaned against the contact of the plug, and the other probe is put on the stripped area. If the signal appears, it indicates that the headphone input section is out of order.

- No signal on the multimeter indicates that another section is damaged. The next cut of the insulation is made 5 cm away from the plug. A new measurement is made. There is a signal - the wire is torn near the plug. No signal - the search continues.

Make cuts in the insulation every 5-10 cm, until the problem area is found. After the repair, the bare wire is insulated. The appearance is not aesthetic, but the headset will work.

Joining wires with a soldering iron: instructions with a step-by-step photo

The gap is found, and it must be eliminated. The most effective way to connect the wires is soldering. It can be considered good luck if only one core is broken and this section is accurately detected. The wire is soldered without cutting the entire cable. Serious damage is repaired by cutting off the problem area, soldering the wires and applying a bandage.

The soldering process is as follows, step by step:

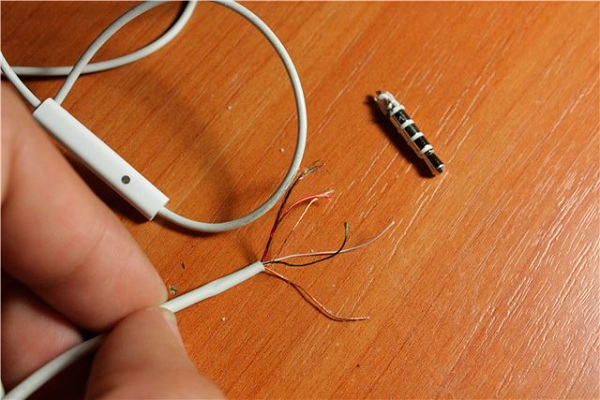

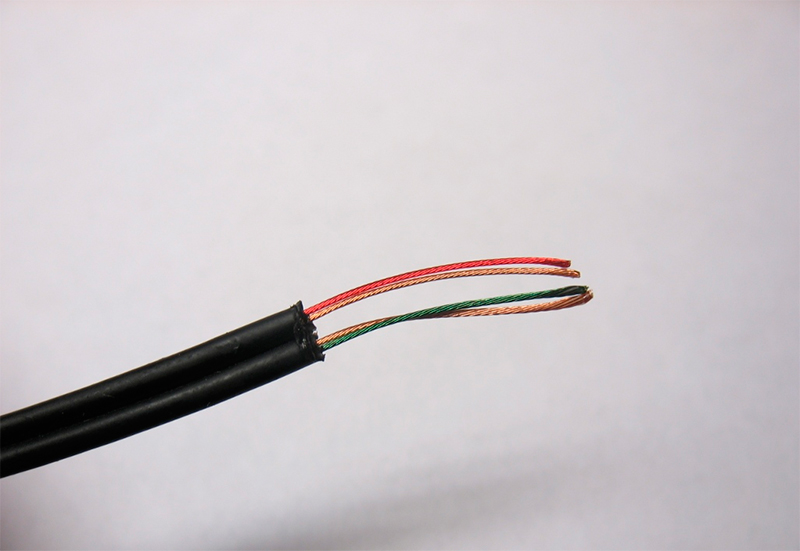

Cut off the damaged section with wire cutters or a knife. At one end of the cable peel off 2-3 cm of the braid to free the wires. The number of wires depends on the model of headphones. A headset with a microphone has 4-5 wires. Simple headphones are connected with 3-4 wires.

Do not be alarmed. The wires are covered with colored insulation, so that you can not mix them up when soldering. There are two twisted wires going to the microphone: a signal wire and a ground wire. They are immediately visible under the braid. The ground wire usually has a yellow insulation color.

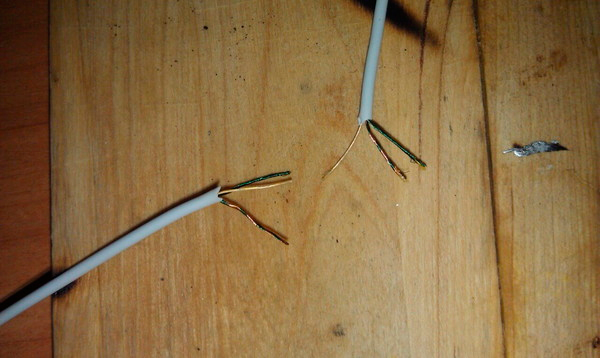

The same procedure is performed with the other end of the cable. When all the cores are free from the braid, their ends are stripped of 5 mm of insulation. You will see a bundle of thin copper hairs, which are twisted clockwise with your fingers.

The contacts are briefly burned with a lighter. The fire will remove the protective varnish from the strands. The firing process is mandatory. The varnish not only interferes with soldering, it is also a dielectric. If the protective layer is not removed, the good solder will grab, but the contact between the connected cores will be poor.

All wire ends must be tinned beforehand. A piece of thick heat shrink tubing is put on the cable braid. This will be the insulation of the band. Similarly, pieces of thin heat-shrink tubing should be put on each core. This will be the insulation of the contacts.

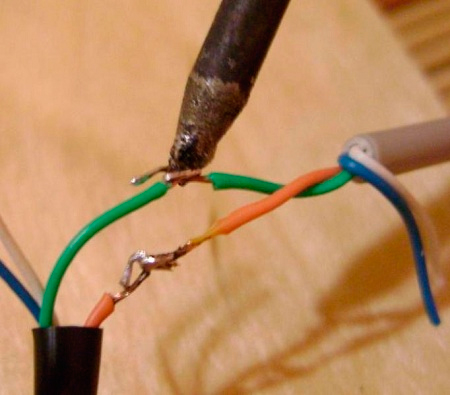

The ends of the tinned wires are twisted, matching the color of the insulation. Each twist is heated with a soldering iron until the tin completely encircles the connection of the wires.

After soldering is complete, check the functionality of the headphones. If the sound in the speakers appeared, proceed to put on the bandage. First, thin heat shrink tubes are put on the strands and heated with a lighter. The insulation will protect the solder strands from shorting out. Tie the resulting bundle of wires together with harsh thread, slip a thick heat shrink tube over the cable braid, and heat it with a lighter.

Joining wires without a soldering iron

Only connect the wires of the headphones by soldering, otherwise there will not be a good contact. If you do not have a soldering iron handy, you will have to resort to alternative methods.

Connecting the wires with solder paste or solder

The method will ensure good contact as it is based on soldering, but the soldering iron is not involved in this process. You will need two tins, solder, rosin and an open source of fire to connect the wire.

When the cable strands are stripped, proceed to primitive soldering:

- Tin is placed in the tin and rosin in the other and heated over an open fire until it begins to melt. The procedure is conveniently performed on a gas stove. When melting begins, the stripped end of each core is first dipped into rosin and then into the tin.

- After about 5 seconds, the copper wire will become silver in color. The tinned ends of the wires are twisted, matching the color of the insulation. The strands are lightly heated with a lighter to solder them. You can simply immerse the connection in molten tin.

After soldering all the wires, the insulation and bandage are applied.

Connecting the wire with simple twists

The method is bad, as it will not provide a normal contact, but if you do not have a soldering iron, a temporary connection of the wire twist will save the situation. The process is simple. The wires are stripped of their insulation and twisted into a tight bundle with your fingers.

Each strand is insulated with tape, electrical tape, or heat shrink tubing. To prevent the wire from breaking, a bandage of heavy thread is put on the connection. For aesthetics, wrap insulation tape or heat shrink tubing on top.

Of all the methods considered, only soldering the wire will ensure the sound quality of the headphones. Twisting is a temporary salvation. They will have to be soldered, otherwise after the oxidation of the copper strands, the sound in the speakers will disappear.

Topical materials:

Making simple headphones and headsets with a microphone yourself

, Top 5 Bluedio Earphones

, Top 5 Bluedio Earphones

, The 5 best headphones under 1000 rubles

, The 5 best headphones under 1000 rubles

, How to connect a microphone to your laptop

, How to connect a microphone to your laptop

, How to clean headphones

, How to clean headphones

, How to disassemble the headphones: step by step instructions with photo of the repair of all headset elements

, How to disassemble the headphones: step by step instructions with photo of the repair of all headset elements

, No sound in headphones

, No sound in headphones

, Decoupling of headphones

, Decoupling of headphones

, Repair of headphones with his own hands

, Repair of headphones with his own hands