A frequent failure of headphones is a broken wire near the plug. This is caused by the fact that during operation this place is exposed to extreme stress. There are two ways out of this situation: buy new ones or solder the plug again. The soldering process is not difficult, and a person who has skills with a soldering iron will cope with it.

The main problem in the repair is the pinout wires. Since the headphones consist of 2-3 pairs of wires, and the headset additionally adds another 1-2 microphones, which does not facilitate the work. Nevertheless, there is no hopeless situation, we will solve the problem gradually.

Content:

Preparing

In the process of work we will need some tools and devices. First and foremost a soldering iron and soldering consumables. In the process of work any tool is used, the power in this case does not matter.

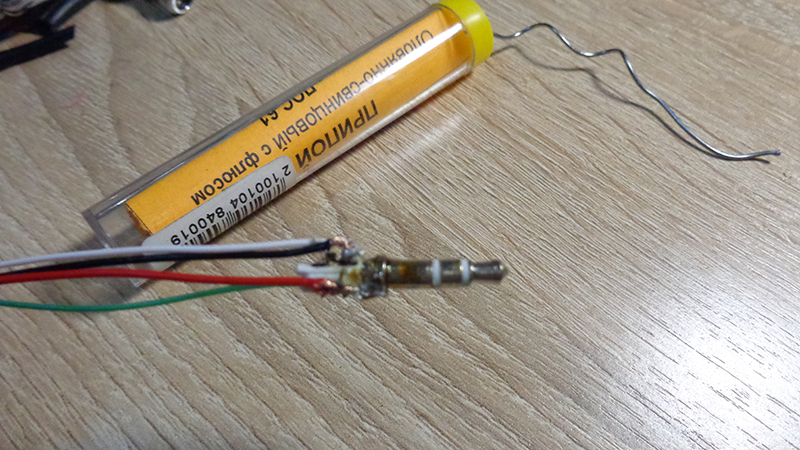

A different approach is needed to consumables. So bought not so long ago solder POS-61, a diameter of 1 mm, turned out to be unsuitable for soldering. When working it turned out to be grainy and matte solidified metal. I had to use POS-40 from the old stock. So the choice of solder should be taken carefully.

The second soldering consumable you need is rosin or flux. The reason I use rosin is because flux is an acid that will eventually destroy the joint. For the same reason I do not recommend to use aspirin tablets as flux, as some internet gurus advise.

Soldering is better, on a wooden surface, as metal or glass takes away heat, which is critical when working with a soldering iron.

Recommendations:

Self-made simple headphones and headset with a microphone

, How to disassemble the headphones: a guide with step-by-step photos of the repair of all headset elements

, How to disassemble the headphones: a guide with step-by-step photos of the repair of all headset elements

, Disassembling headphones

, Disassembling headphones

In the work we will need:

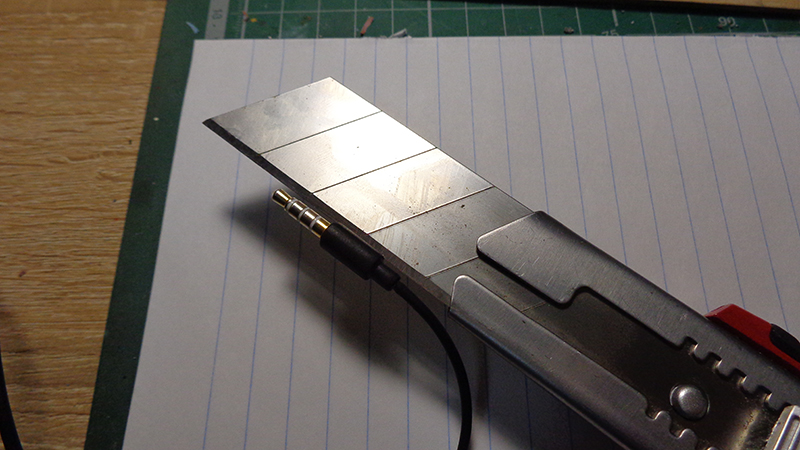

- A sharp knife, a mounting knife or an electrician's knife, not so important. It is needed to remove the insulation.

- Sandpaper to clean the contact area and heat shrink tube 4-5 mm in diameter.

- Don't forget the pliers or the pliers for holding the parts during the soldering process.

Soldering

First cut the plug body from the headphone wire with wire cutters or a knife on the pad. You can immediately strip the ends of the wires, and burn the metal to remove the varnish.

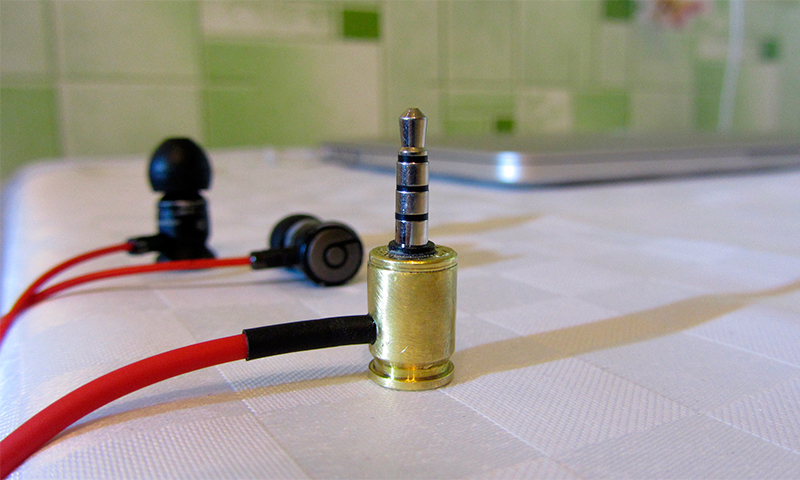

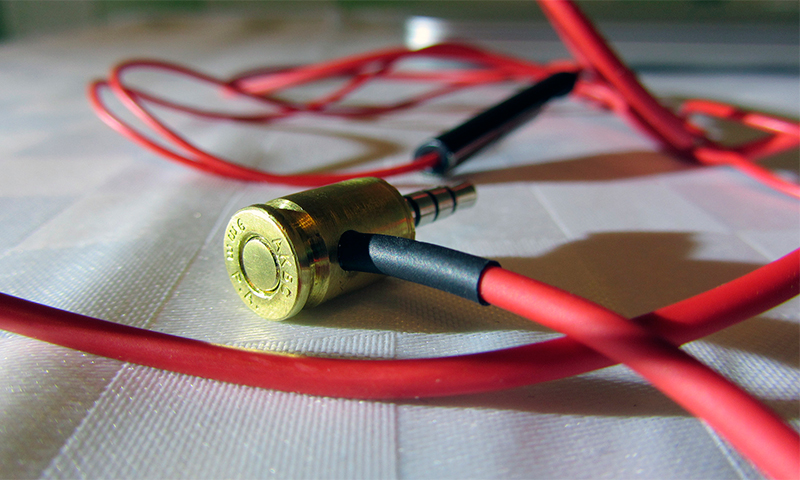

The headphone plug itself is enclosed in a monolithic housing. Nevertheless, you will have to remove the plastic or rubber-like material to work with it. All you need is a sharp knife, in this case I use an assembly knife, because for me it is the most convenient to work with. With the knife we carefully cut the body of the plug along the seam of the press.

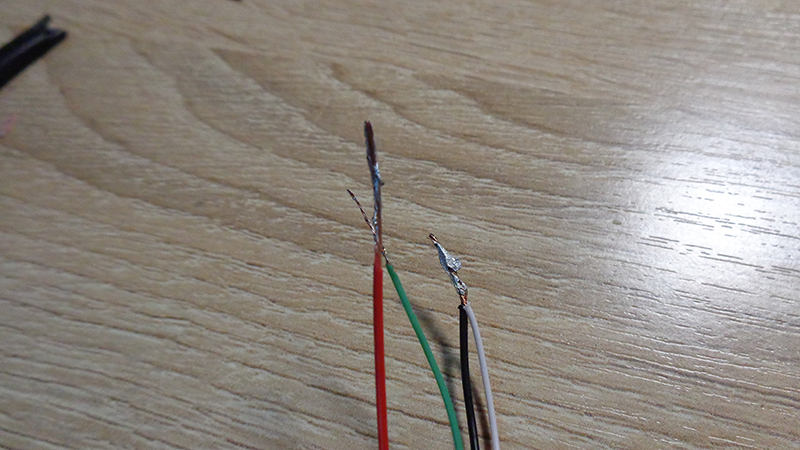

After that, manually remove the remaining rubber or plastic from the plug body. At this time, pay attention to the location of the wires, they usually differ in color, so remember or make a diagram of the location. So that in the future, know which wire, in which socket to solder. The best way is to draw an approximate diagram.

Next, clean the ends of the headphone wires from the insulation. We burn their ends - this will get rid of varnish, or slightly pass them with sandpaper. In the photo you can see the cleaned and ready to work plug and the prepared wires. The left one is in green insulation, the right one is in red. The white and black are common, go into the same socket, for this reason they are twisted.

After preparation, to make it easier to solder them, let's tin them. The tinning process is simple. After dipping the wire in rosin or flux, we put a thin layer of solder on the metal surface with the soldering iron. The surface of the wire turns a silver color.

The ends of the wire in the photo are a bit long, I had to cut them a little bit later, leaving the ends about 5 mm each.

Next, before soldering we need to think about the plug housing, because the original one is cut and removed. So we first put a piece of heat shrink tubing on the headphone wire, which will act as a hard insulator for the wire at the plug and a cone tip from a ballpoint pen with the narrow edge cut off. Check how everything fits and sits in place. Before soldering, place the heat shrink tube and cone on the headphone wire.

Then we begin soldering. Take some solder on the tip of the soldering iron, dip it in rosin and quickly transfer it to the soldering point. It is important to take just the right amount of solder. The solder itself should be silver color with a slight gloss, the connection should be strong enough.

After soldering, check the functionality of the headphones. Do not forget that the plug is still hot after work, you should not take it in your hands immediately after the soldering iron. You can check the operation of the headphones by testing the wires, as well as by the usual inclusion of unfinished headphones in the socket of the phone or player. If everything works, then proceed to the design of the plug housing, but if not, check the contacts again.

The connection itself looks like this, but it is still better to smooth out the protrusions. After checking, if everything works, slide the heat shrink tube over the plug. Then heat it with a construction hair dryer or a regular candle flame, like in my case. It looks a little scary, but I think this is quite fixable later on. After shrinking the insulator into place, move the auto-pen cone forward to the desired position.

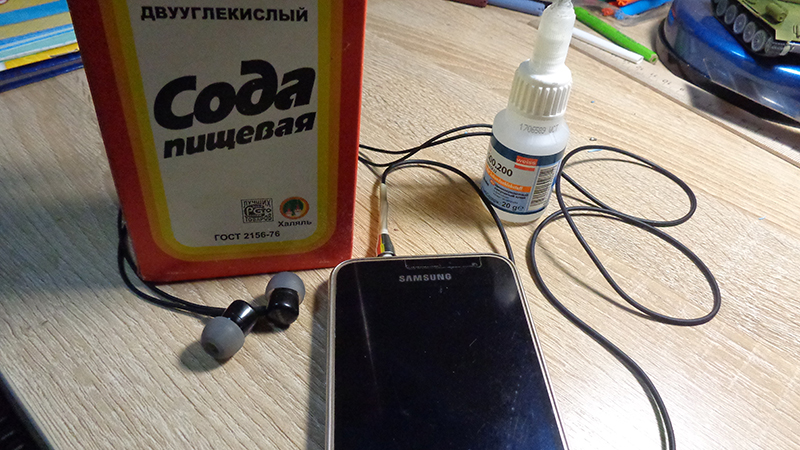

In order to fix our fastener, and fill the void in the cone, you can use epoxy resin, or as in my case - a mixture of soda and cyanoacrylate adhesive "Cosmophen"

It is worth bearing in mind that this mixture hardens very quickly, so you have to work with it quickly and carefully. The upper joint after that we grind with sandpaper and that's it, the plug is ready.

About pinning

How to connect torn headphone wires

Depending on the type of headphones to the plug is connected to a certain number of wires:

- mono headphones - 2 wires;

- Stereo headphones, 3 wires, less common mono-headphones with a common wire;

- stereo headphones with 4 wires, 2 common, in one jack;

- headset, 5-6 wires, extra for the microphone.

If 2-4 wires are usually not a problem, then with a lot of wires you need to carefully and carefully open the plug housing, in order to know which wire, in which socket to solder.

The second option, in this case, is to wire the channels with a device, or to determine the type of connection by the color of the wires. There is still no single standard for the color of wire insulation.

Repair headphones with your own hands

A common variant of distribution according to the color of the insulation:

- red - right channel;

- green or blue - left channel;

- Colorless, yellow - common wire.

But again, there is no standard color distribution.

The headset has one or two additional wires for the microphone, soldering according to the scheme is not a problem, the scheme itself is worth looking at either when dissecting the plug fasteners, or to probe with a device. If you have 6 or more wires, which is also sometimes the case with headsets, you will have to test all the wires one by one and determine which wire goes where.

Thus, to repair the plug on the headphones problem solvable, besides requiring a minimum of expense if you know how to work the soldering iron.

Topical materials:

The 5 best headphones under 1000 rubles

, 5 best stereo headphones

, 5 best stereo headphones

, If the water got on the headphones or inside the connector of the cell phone

, If the water got on the headphones or inside the connector of the cell phone

, How to protect headphones from mechanical damage and strengthen the wire

, How to protect headphones from mechanical damage and strengthen the wire

, How to connect wireless headphones to your phone

, How to connect wireless headphones to your phone

, How to warm up headphones and if you need to do it

, How to warm up headphones and if you need to do it

, How to fix your own headphones if one stops working

, How to fix your own headphones if one stops working

, No sound in headphones

, No sound in headphones

, Headphone pinout

, Headphone pinout